Izingubo ezisebenza kahle ezilapheka nge-UV zisetshenziswe iminyaka eminingi ekwenzeni iphansi, ifenisha, namakhabethe. Esikhathini esiningi salesi sikhathi, i-100% -i-solid ne-solvent-based ye-UV-therapy iwubuchwepheshe obuhamba phambili emakethe. Eminyakeni yamuva nje, ubuchwepheshe bokumboza be-UV obusekelwe emanzini bukhulile. Ama-resin asekelwe emanzini e-UV-curable afakazele ukuthi ayithuluzi eliwusizo kubakhiqizi ngenxa yezizathu ezihlukahlukene, okuhlanganisa ukudlula ibala le-KCMA, ukuhlolwa kokumelana namakhemikhali, nokunciphisa ama-VOC. Ukuze lobu buchwepheshe buqhubeke bukhula kule makethe, abashayeli abambalwa bakhonjwe njengezindawo ezibalulekile lapho kufanele kwenziwe khona ukuthuthukiswa. Lokhu kuzothatha ama-resin asekelwe emanzini e-UV-curable ngaphandle nje kokuba "nento okufanele ube nayo" enawo ama-resin amaningi. Bazoqala ukungeza izakhiwo ezibalulekile ekwengezeni, okuletha inani endaweni ngayinye eduze kochungechunge lwenani ukusuka kumenzi wezinto ezinamathelayo kuye kusifakeli sefekthri kuya kusifaki, futhi, ekugcineni, kumnikazi.

Abakhiqizi, ikakhulukazi namuhla, bafisa ukunamathela okuzokwenza okungaphezu nje kokudlulisa imininingwane. Kukhona nezinye izakhiwo ezihlinzeka ngezinzuzo ekukhiqizeni, ekupakisheni nasekufakeni. Esinye sezici ezifiselekayo ukuthuthukisa ukusebenza kahle kwezitshalo. Ngokwemboza okusekelwe emanzini lokhu kusho ukukhululwa kwamanzi ngokushesha kanye nokumelana nokuvinjwa okusheshayo. Esinye isibaluli esifiselekayo ukuthuthukisa ukuqina kwe-resin ukuze kuthathwe/kusetshenziswe kabusha i-coating, nokuphathwa kohlu lwazo. Kumsebenzisi wokugcina nesifaki, izibaluli ezifiselekayo zingcono ukumelana nokushiswa futhi azikho izimpawu zensimbi phakathi nokufakwa.

Lesi sihloko sizodingida intuthuko entsha kuma-polyurethanes e-UV-curable e-UV asekelwe emanzini anikeza ukusimama kopende okungu-50 °C okuthuthuke kakhulu ekucaceni, kanye nezingubo ezinemibala. Iphinde idingide ukuthi la ma-resin abhekana kanjani nezimfanelo ezifiselekayo ze-coating applicator ekwandiseni isivinini somugqa ngokusebenzisa ukukhishwa kwamanzi okusheshayo, ukuphikiswa okuthuthukisiwe kwe-block, nokumelana ne-solvent ngaphandle komugqa, okuthuthukisa isivinini sokupakisha nokupakisha imisebenzi. Lokhu kuzophinde kuthuthukise umonakalo ongekho kulayini owenzeka ngezinye izikhathi. Lesi sihloko siphinde sidingide ukuthuthukiswa okukhonjiswe ekuphikeleni amabala namakhemikhali okubalulekile kubafaki nabanikazi.

Ingemuva

Isimo semboni yezingubo zokugqoka sihlala sishintsha. "Okufanele ube nakho" kokumane udlulise ukucaciswa ngentengo efanelekile nge-mil ngayinye esetshenzisiwe akwanele. Ukuma kwezingubo zokugqoka ezifakwe efekthri ku-cabinery, joinery, flooring, kanye nefenisha kuyashintsha ngokushesha. Abakhiqizi abahlinzeka ngezingubo ezimbonini bayacelwa ukuthi benze okokunamathela kuphephe ukuze abasebenzi bakufake, basuse izinto ezikhathazayo kakhulu, bafake ama-VOC ngamanzi, futhi basebenzise ngisho nekhabhoni encane yezinsalela ezimbiwa phansi kanye ne-bio carbon eyengeziwe. Iqiniso liwukuthi kukho konke ochungechungeni lwenani, ikhasimende ngalinye licela i-coating ukuthi yenze okungaphezu nje kokuhlangabezana nemibandela.

Ngokubona ithuba lokudala inzuzo eyengeziwe yefekthri, ithimba lethu laqala ukuphenya ezingeni lefekthri ngezinselelo laba bafake izicelo ababebhekene nazo. Ngemva kwezingxoxo eziningi saqala ukuzwa izindikimba ezivamile:

- Izithiyo zokuvumela zivimbela imigomo yami yokwandisa;

- Izindleko ziyanda futhi nesabelomali sethu semali siyehla;

- Izindleko zakho kokubili amandla nezisebenzi ziyanda;

- Ukulahlekelwa abasebenzi abanolwazi;

- Imigomo yethu yenkampani ye-SG&A, kanye naleyo yekhasimende lami, kufanele kuhlangatshezwane nayo; futhi

- Umncintiswano waphesheya kwezilwandle.

Lezi zindikimba ziholele ezitatimendeni ze-value-proposition ezaqala ukuzwakala kubasebenzisi be-polyurethanes e-UV-curable ye-UV esekelwe emanzini, ikakhulukazi endaweni yemakethe yokuhlanganisa kanye nekhabhinethi njengokuthi: "Abakhiqizi be-joinery kanye ne-cabinetry bafuna ukuthuthukiswa kokusebenza kahle kwefekthri" futhi "abakhiqizi bafuna ikhono lokukhulisa ukukhiqiza emigqeni emifushane yokukhiqiza enomonakalo omncane wokulungisa kabusha amanzi ngenxa yokulimala okuncane kokusebenza kabusha."

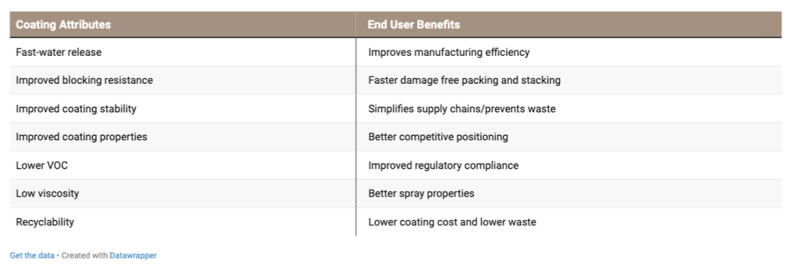

Ithebula 1 libonisa ukuthi, kumkhiqizi wezinto zokusetshenziswa zokumboza, ukuthuthukiswa kwezimfanelo ezithile zokumboza kanye nezakhiwo ezibonakalayo kuholela ekusebenzeni kahle okungatholwa umsebenzisi wokugcina.

ITAFULA 1 | Izimfanelo nezinzuzo.

Ngokuklama ama-PUD elapheka e-UV anezimfanelo ezithile njengoba zibhalwe kuThebula 1, abakhiqizi abasebenzisa ekugcineni bazokwazi ukubhekana nezidingo abanazo ekuthuthukiseni ukusebenza kahle kwezitshalo. Lokhu kuzozivumela ukuthi zikwazi ukuncintisana kakhulu, futhi ngokunokwenzeka kuzivumele ukuthi zandise ukukhiqizwa kwamanje.

Imiphumela Yokuhlola Nengxoxo

Umlando wokuhlakazeka kwe-UV-Curable Polyurethane

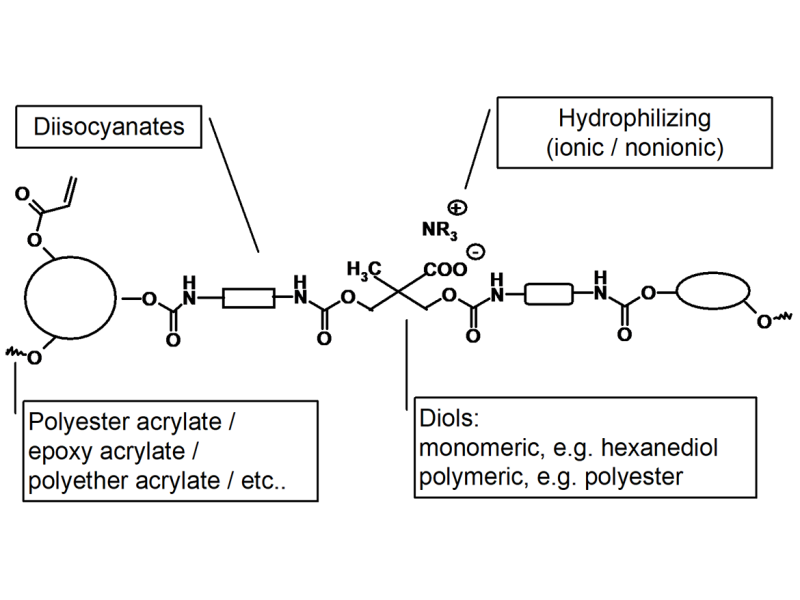

Ngawo-1990, ukusetshenziswa kwezentengiselwano kwama-anionic polyurethane dispersions aqukethe amaqembu e-acrylate axhunywe ku-polymer kwaqala ukusetshenziswa ekusetshenzisweni kwezimboni.1 Eziningi zalezi zicelo zazisezipakishweni, ziyinki, kanye nezingubo zokhuni. Umfanekiso 1 ubonisa ukwakheka kwejenerikhi ye-PUD eyelapheka yi-UV, ekhombisa ukuthi lezi zinto zokusetshenziswa zokwemboza zenziwa kanjani.

UMFANEKISO 1 | I-generic acrylate esebenzayo ye-polyurethane dispersion.3

Njengoba kukhonjisiwe kuMfanekiso 1, ama-UV-curable polyurethane dispersions (ama-UV-curable UV), akhiwe izingxenye ezijwayelekile ezisetshenziselwa ukwenza i-polyurethane dispersions. I-aliphatic diisocyanate isabela nama-ester ajwayelekile, ama-diol, amaqembu e-hydrophilization, kanye nezandisi zamaketango ezisetshenziselwa ukwenza i-polyurethane dispersions.2 Umehluko uwukwengezwa kwe-acrylate functional ester, epoxy, noma ama-ether afakwe esinyathelweni sangaphambili se-polymer ngenkathi enza ukusabalalisa. Ukukhethwa kwezinto ezisetshenziswa njengamabhulokhi wokwakha, kanye nezakhiwo ze-polymer nokucubungula, kunquma ukusebenza kwe-PUD nezici zokomisa. Lokhu kukhetha ezintweni ezingavuthiwe nasekucutshungulweni kuzoholela kuma-PUD alapheka yi-UV angase abe ukwakheka okungezona ifilimu, kanye nalawo enza ifilimu.3 Izinhlobo zefilimu ezakha, noma zokomisa, ziyisihloko salesi sihloko.

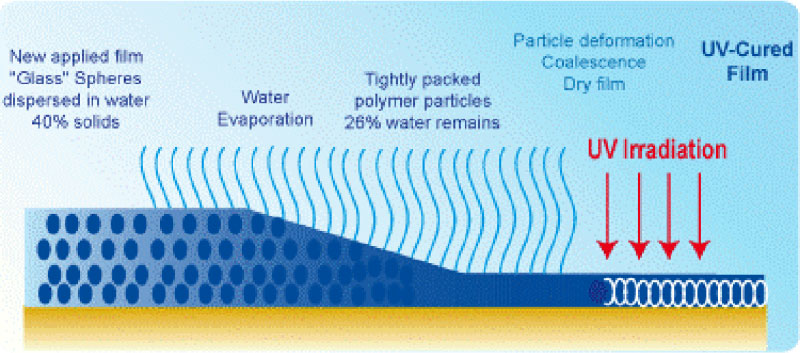

Ukwakhiwa kwefilimu, noma ukomiswa njengoba kuvame ukubizwa kanjalo, kuzokhipha amafilimu ahlanganisiwe omile lapho kuthintwa ngaphambi kokwelashwa kwe-UV. Ngenxa yokuthi abafake izicelo bafisa ukukhawulela ukungcoliswa komoya kwe-coating ngenxa yezinhlayiya, kanye nesidingo sejubane enqubweni yabo yokukhiqiza, lezi zivame ukomiswa kumahhavini njengengxenye yenqubo eqhubekayo ngaphambi kokwelashwa kwe-UV. Umfanekiso wesi-2 ubonisa inqubo evamile yokomisa kanye neyokwelapha ye-PUD eyelapheka yi-UV.

UMFANEKISO 2 | Inqubo yokwelapha i-PUD eyelapheka yi-UV.

Indlela yokufaka esetshenziswayo ivamise ukufutha. Nokho, kusetshenziswe ummese phezu komqulu ngisho nejazi lezikhukhula. Uma sekusetshenzisiwe, ukumboza ngokuvamile kuzodlula inqubo yezinyathelo ezine ngaphambi kokuthi kusingathwe futhi.

1.I-Flash: Lokhu kungenziwa ekamelweni noma emazingeni okushisa aphakeme imizuzwana embalwa ukuya emaminithini ambalwa.

2. Ihhavini yomile: Yilapho amanzi kanye nezincibilikisi ezihlanganiswayo kukhishwa khona ekunambeni. Lesi sinyathelo sibalulekile futhi ngokuvamile sisebenzisa isikhathi esiningi kunqubo. Lesi sinyathelo sivamise ukuba ku->140 °F futhi sihlala amaminithi angu-8. Amahhavini okomisa amazoni amaningi nawo angasetshenziswa.

- Isibani se-IR kanye nokunyakaza komoya: Ukufakwa kwezibani ze-IR namafeni okunyakaza komoya kuzosheshisa ukukhanya kwamanzi ngokushesha okukhulu.

3.Ukwelashwa kwe-UV.

I-4.Cool: Uma usuphulukisiwe, ukugqoka kuzodinga ukwelapha isikhathi esithile ukuze kuzuzwe ukumelana nokuvimbela. Lesi sinyathelo singase sithathe imizuzu eyi-10 ngaphambi kokuthi ukuvinjwa kufinyelelwe

Okokuhlola

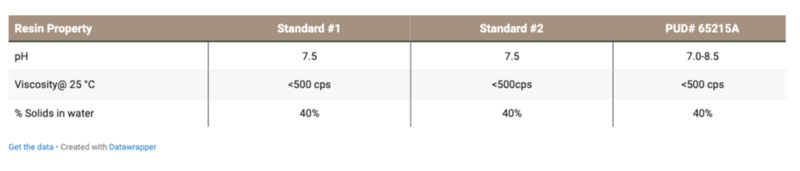

Lolu cwaningo luqhathanise ama-PUD amabili e-UV (i-WB UV), asetshenziswa njengamanje kukhabhinethi nemakethe yokuhlanganisa, nentuthuko yethu entsha, i-PUD # 65215A. Kulolu cwaningo siqhathanisa i-Standard #1 kanye ne-Standard #2 ne-PUD #65215A ekomisweni, ukuvinjelwa, nokumelana namakhemikhali. Siphinde sihlole ukuzinza kwe-pH nokuzinza kwe-viscosity, okungaba bucayi uma kucatshangelwa ukuphinda kusetshenziswe isifutho esiningi nempilo yeshelufu. Okuboniswe ngezansi kuThebula 2 yizimo ezibonakalayo zenhlaka ngayinye esetshenziswe kulolu cwaningo. Zontathu izinhlelo zakhiwe ezingeni elifanayo le-photoinitiator, ama-VOC, nezinga eliqinile. Womathathu ama-resin akhiwe nge-co-solvent engu-3%.

ITAFULA 2 | Izici ze-PUD resin.

Sitshelwe ezingxoxweni zethu ukuthi iningi lezingubo ze-WB-UV ezimakethe zokuhlanganisa nezimakethe zekhabhinethi zoma emgqeni wokukhiqiza, okuthatha phakathi kwemizuzu engu-5-8 ngaphambi kokwelashwa kwe-UV. Ngokuphambene, ulayini we-UV (SB-UV) osuselwa ku-solvent yoma emizuzwini emi-3-5. Ngaphezu kwalokho, kule makethe, izimbobo ngokuvamile zisetshenziswa 4-5 mils ezimanzi. Ukuhlehla okukhulu emanzini okunamathela kwe-UV-ilapheka uma kuqhathaniswa nezinye izindlela ezisekelwe ku-UV ezincibilikayo isikhathi esithathayo ukukhanyisa amanzi emgqeni wokukhiqiza.4 Ukukhubazeka kwefilimu okufana namabala amhlophe kuzokwenzeka uma amanzi engakakhanyisi kahle kusukela ekunambeni ngaphambi kokwelapha kwe-UV. Lokhu kungenzeka futhi uma ubukhulu befilimu obumanzi buphezulu kakhulu. Lawa machashazi amhlophe adaleka lapho amanzi evaleleka ngaphakathi kwefilimu ngesikhathi sokwelashwa kwe-UV.5

Kulolu cwaningo sikhethe ishejuli yokwelapha efana naleyo ezosetshenziswa emugqeni osuselwa kuncibilikiseli owelapheka nge-UV. Umfanekiso wesi-3 ubonisa uhlelo lwethu lokusebenza, ukomisa, ukuphulukisa, kanye nohlelo lokupakisha olusetshenziselwa isifundo sethu. Lolu hlelo lokumisa lumelela ukuthuthuka okuphakathi kuka-50% kuya ku-60% wejubane lomugqa lilonke ngaphezu kwezinga lemakethe lamanje ekufakweni kwezicelo zokuhlanganisa kanye nekhabhinethi.

UMFANEKISO 3 | Uhlelo lokusebenza, ukomisa, ukuphulukisa, kanye nohlelo lokupakisha.

Ngezansi kunezimo zohlelo lokusebenza nezimo zokwelapha esizisebenzise ocwaningweni lwethu:

●Fafaza phezu kwe-maple veneer nge-basecoat emnyama.

● I-flash yezinga lokushisa legumbi lamasekhondi angu-30.

●140 °F ihhavini yokomisa imizuzu engu-2.5 (i-convection oven).

● Ukwelashwa kwe-UV - amandla acishe abe ngu-800 mJ/cm2.

- Izindwangu ezicacile zelashwa kusetshenziswa isibani se-Hg.

- Izembatho ezinemibala yelashwe kusetshenziswa inhlanganisela yesibani Hg/Ga.

●Iminithi elingu-1 lokuphola ngaphambi kokunqwabelanisa.

Ocwaningweni lwethu siphinde safafaza ugqinsi lwefilimu emanzi emithathu ehlukene ukuze sibone ukuthi ezinye izinzuzo ezifana namajazi ambalwa nazo zizofezeka yini. I-4 mils emanzi yiyona ejwayelekile ye-WB UV. Kulolu cwaningo siphinde safaka izicelo zokumboza ezimanzi eziyi-6 kanye ne-8.

Ukwelapha Imiphumela

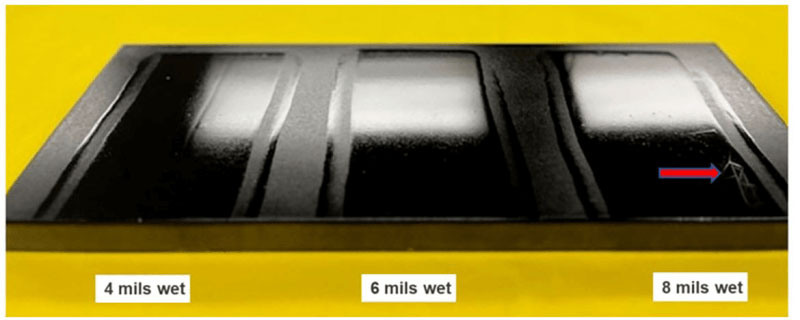

I-Standard #1, i-high-gloss clear coat, imiphumela iboniswa ku-Figure 4. I-WB UV ecacile yokugqoka isetshenziswe ku-fiberboard ephakathi nendawo (MDF) ngaphambili eyayimbozwe nge-basecoat emnyama futhi yelashwa ngokuvumelana neshejuli ekhonjiswe kuMfanekiso 3. Ku-4 mils emanzi ama-coating passes. Kodwa-ke, ngo-6 kanye ne-8 mils isicelo esimanzi i-coating yaqhekeka, futhi ama-mils angu-8 asuswa kalula ngenxa yokukhishwa kwamanzi okungekuhle ngaphambi kokwelashwa kwe-UV.

UMFANEKISO 4 | Okujwayelekile #1.

Umphumela ofanayo uyabonakala futhi kuZinga #2, eliboniswe kuMfanekiso 5.

UMTHETHO 5 | Okujwayelekile #2.

Kuboniswe kuMfanekiso 6, kusetshenziswa ishejuli yokuphulukisa efanayo njengakuMfanekiso 3, i-PUD #65215A ibonise ukuthuthuka okukhulu ekukhululweni/ukomisa kwamanzi. Kubukhulu befilimu obumanzi obungu-8 mils, ukuqhekeka okuncane kubonwe emaphethelweni angezansi esampula.

UMTHETHO 6 | I-PUD #65215A.

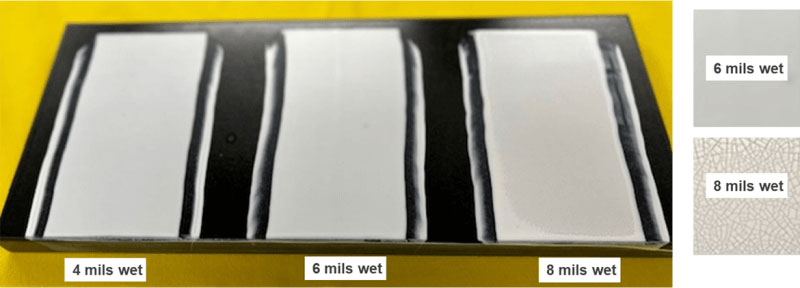

Ukuhlolwa okwengeziwe kwe-PUD# 65215A ku-coat ecwebezelayo ephansi kanye ne-pigmented coat phezu kwe-MDF efanayo ne-basecoat emnyama kwahlaziywa ukuze kuhlolwe izici zokukhishwa kwamanzi kwezinye izinto ezijwayelekile zokuhlanganisa. Njengoba kuboniswe kuMfanekiso 7, ukwakheka kwe-low-gloss ku-5 kanye ne-7 mils isicelo esimanzi sakhulula amanzi futhi sakha ifilimu enhle. Kodwa-ke, ku-10 mils emanzi, bekuminyene kakhulu ukukhulula amanzi ngaphansi kohlelo lokumisa nokuphulukisa kuMfanekiso 3.

UMFANEKISO 7 | I-PUD ecwebezelayo ephansi #65215A.

Kufomula enemibala emhlophe, i-PUD #65215A yenze kahle ohlelweni olufanayo lokumisa nokuphulukisa oluchazwe kuMfanekiso 3, ngaphandle uma isetshenziswe ku-8 wet mils. Njengoba kuboniswe ku-Figure 8, ifilimu iqhekeka ku-8 mils ngenxa yokukhululwa kwamanzi okungekuhle. Sekukonke ekubunjweni okucacile, okucwebezelayo okuphansi, nokunemibala, i-PUD# 65215A yenze kahle ekubunjweni kwefilimu nokomisa lapho isetshenziswa kufika ku-7 mils imanzi futhi yelashwa ohlelweni lokusheshisa lokumisa nokuphulukisa oluchazwe kuMfanekiso 3.

UMFANEKISO 8 | I-PUD Enemibala #65215A.

Ukuvimba Imiphumela

Ukuvimbela ukumelana yikhono le-coating lokunganamatheli kwesinye isiqephu sendatshana esinamekiwe lapho sistakiwe. Ekukhiqizeni lokhu kuvame ukuba yibhodlela uma kuthatha isikhathi ukuthi i-coating ephulukisiwe ifinyelele ukumelana ne-block. Kulolu cwaningo, ukwakheka okunemibala ye-Standard #1 kanye ne-PUD #65215A kusetshenziswe engilazini emanzi angu-5 kusetshenziswa ibha yokudonsa. Lezi zelashwa ngayinye ngokweshejuli yokuphulukisa kuMfanekiso 3. Amaphaneli amabili engilazi aboshwe aphulukiswa ngesikhathi esifanayo - emaminithini angu-4 ngemva kokwelashwa amaphaneli ayehlanganiswe ndawonye, njengoba kuboniswe kuMfanekiso 9. Ahlala eboshwe ndawonye ekamelweni lokushisa amahora angu-24. Uma amaphaneli ahlukaniswa kalula ngaphandle kokuphrinta noma ukulimala kumaphaneli aboshwe ngakho ukuhlolwa kwakubhekwa njengokudlula.

Umfanekiso we-10 ubonisa ukumelana nokuvimbela okuthuthukisiwe kwe-PUD# 65215A. Nakuba kokubili i-Standard #1 ne-PUD #65215A zithole ukwelashwa okugcwele esivivinyweni sangaphambilini, yi-PUD #65215A kuphela ebonise ukukhishwa kwamanzi okwanele kanye nokwelapha ukuze kuzuzwe ukumelana nokuvinjwa.

UMTHETHO 9 | Ukuvimbela ukuhlolwa komfanekiso wokumelana.

UMFANEKISO 10 | Ukuvimbela ukumelana kwe-Standard #1, kulandelwa i-PUD #65215A.

Acrylic Blending Imiphumela

Abakhiqizi bezinto zokumboza bavame ukuhlanganisa ama-resin e-WB elaphekayo e-UV nama-acrylic ukuze kwehlise izindleko. Ocwaningweni lwethu siphinde sabheka ukuhlanganisa i-PUD#65215A ne-NeoCryl® XK-12, i-acrylic esekwe emanzini, evame ukusetshenziswa njengozakwethu ohlanganisayo wama-PUD asekelwe emanzini alapheka e-UV emakethe yokuhlanganisa nekhabethe. Kule makethe, ukuhlolwa kwebala kwe-KCMA kuthathwa njengokujwayelekile. Ngokuya ngesicelo sokusetshenziswa kokugcina, amanye amakhemikhali azobaluleke kakhulu kunamanye kumkhiqizi we-athikili ehlanganisiwe. Isilinganiso esingu-5 sihamba phambili futhi isilinganiso esingu-1 sibi kakhulu.

Njengoba kukhonjisiwe kuThebula 3, i-PUD #65215A isebenza kahle kakhulu ekuhloleni amabala e-KCMA njengokucwebezela okuphezulu okucacile, okucwebezelayo okuphansi, nanjengengubo enemibala. Ngisho noma kuhlanganiswe 1:1 nge-acrylic, ukuhlolwa kwamabala e-KCMA akuthikamezeka kakhulu. Ngisho nasekungcolisweni ngama-ejenti afana nesinaphi, ukumbozwa kwabuyela ezingeni elamukelekayo ngemva kwamahora angu-24.

ITAFULA 3 | Ukumelana namakhemikhali namabala (isilinganiso esingu-5 singcono kakhulu).

Ngokungeziwe ekuhloleni amabala e-KCMA, abakhiqizi bazophinde bahlolele ukwelashwa ngokushesha ngemuva kokwelashwa kwe-UV emugqeni. Ngokuvamile imiphumela yokuxuba i-acrylic izobonakala ngokushesha ngaphandle komugqa wokwelapha kulokhu kuhlolwa. Okulindelekile ukuthi kungabi nokugqama kokugqama ngemuva kwama-20 isopropyl alcohol rubs (20 IPA dr). Amasampuli ahlolwa iminithi elingu-1 ngemva kokwelashwa kwe-UV. Ekuhlolweni kwethu sibonile ukuthi inhlanganisela engu-1:1 ye-PUD# 65215A ene-acrylic ayizange iphumelele lokhu kuhlolwa. Nokho, sibonile ukuthi i-PUD #65215A ingase ihlanganiswe ne-25% NeoCryl XK-12 acrylic futhi isaphumelele ukuhlolwa kwe-20 IPA dr (i-NeoCryl wuphawu lokuthengisa olubhalisiwe lweqembu le-Covestro).

UMFANEKISO 11 | 20 IPA ukuhlikihlwa kabili, iminithi elingu-1 ngemva kokwelashwa kwe-UV.

I-Resin Stability

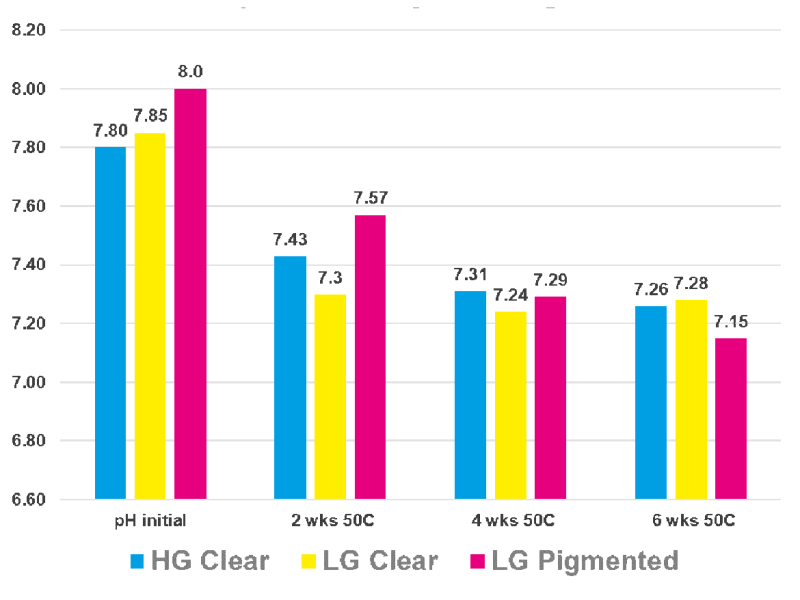

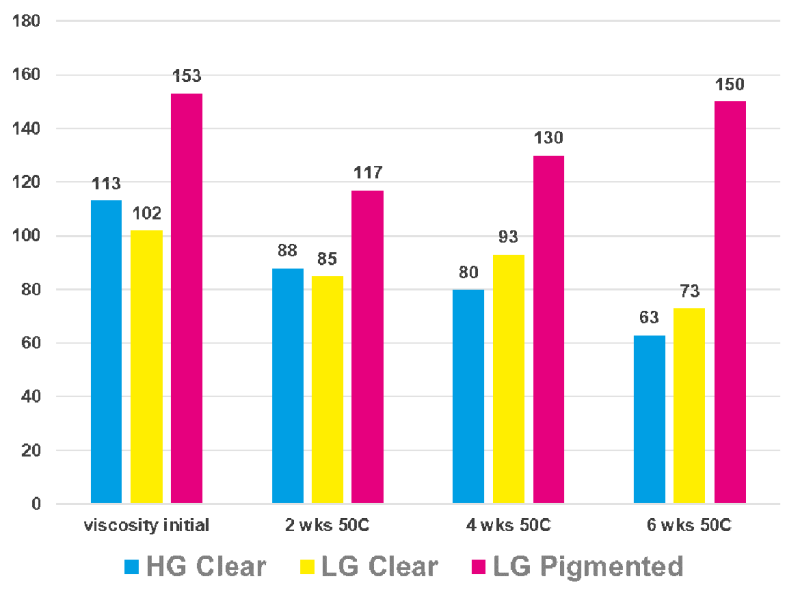

Ukuzinza kwe-PUD #65215A nakho kwahlolwa. Ukwakhiwa kuthathwa njengeshalofu elizinzile uma ngemva kwamasonto angu-4 ku-40 ° C, i-pH ingehli ngaphansi kuka-7 futhi i-viscosity ihlala izinzile uma iqhathaniswa neyokuqala. Ekuhlolweni kwethu sinqume ukubeka amasampula ezimeni eziqinile ezifika kumaviki ayi-6 ku-50 °C. Kule mibandela Izinga #1 kanye ne-#2 bezingazinzile.

Ekuhloleni kwethu sibheke ukucwebezela okuphezulu okucacile, okucwebezelayo okuphansi, kanye nokubunjwa okunemibala ekhanyayo ephansi esetshenziswe kulolu cwaningo. Njengoba kubonisiwe kuMfanekiso 12, ukuzinza kwe-pH yakho konke okuthathu kwakhiwe kwahlala kuzinzile futhi ngaphezu komkhawulo we-pH ongu-7.0. Umfanekiso we-13 ubonisa ushintsho oluncane lwe-viscosity ngemva kwamaviki angu-6 ku-50 °C.

UMFANEKISO 12 | Ukuzinza kwe-pH ye-PUD eyenziwe #65215A.

UMFANEKISO 13 | Ukuzinza kwe-Viscosity kwe-PUD eyenziwe #65215A.

Olunye uvivinyo olubonisa ukusebenza kokuqina kwe-PUD #65215A bekuwukuphinda kuvivinye ukumelana namabala e-KCMA kokwakheka kokumboza osekuguge amasonto ayi-6 ku-50 °C, futhi kuqhathaniswa lokho nokumelana kwayo namabala kwe-KCMA kokuqala. Izembatho ezingabonisi ukuzinza okuhle zizobona ukwehla ekusebenzeni kwamabala. Njengoba kubonisiwe kuMfanekiso 14, i-PUD# 65215A igcine izinga lokusebenza elifanayo njengoba lenza ekuhlolweni kokuqala kokumelana namakhemikhali/ibala lokumboza okunemibala eboniswe kuThebula 3.

UMTHETHO 14 | Amaphaneli okuhlola amakhemikhali e-PUD enombala #65215A.

Iziphetho

Kwabafaka izicelo zezingubo ezisekelwe emanzini ezilapheka nge-UV, i-PUD #65215A izobenza bakwazi ukuhlangabezana nezindinganiso zamanje zokusebenza ezimakethe zokuhlanganisa, ukhuni kanye nekhabhinethi, futhi ngaphezu kwalokho, kuzovumela inqubo yokumboza ukuthi ibone ukuthuthuka kwesivinini somugqa sibe ngaphezu kuka-50-60% ngaphezu kwezingubo zamanje ezisekelwe emanzini ezilapheka e-UV. Kumfakisicelo lokhu kungase kusho:

● Ukukhiqizwa okusheshayo;

● Ukuqina kwefilimu okwenyuka kunciphisa isidingo samajazi engeziwe;

● Imigqa eyomisa emifushane;

●Ukonga ugesi ngenxa yokuncipha kwezidingo zokomisa;

● I-scrap encane ngenxa yokumelana nokuvinjelwa okusheshayo;

● Imfucumfucu encishisiwe ngenxa yokuqina kwe-resin.

Ngama-VOC angaphansi kuka-100 g/L, abakhiqizi bayakwazi futhi ukuhlangabezana nezinhloso zabo ze-VOC. Kubakhiqizi okungenzeka banezinkinga zokunwetshwa ngenxa yezinkinga zezimvume, i-PUD #65215A ekhipha amanzi ngokushesha izobenza bakwazi ukuhlangabezana kalula nezibopho zabo zokulawula ngaphandle kokuzinikela kokusebenza.

Ekuqaleni kwalesi sihloko sicaphune ezingxoxweni zethu ukuthi abafaki bezinto ezilapheka nge-UV ezincibilikisiwe ngokuvamile bazokoma futhi belaphe okunamathelayo ngenqubo ethatha phakathi kwemizuzu engu-3-5. Sikhombisile kulolu cwaningo ukuthi ngokwenqubo ekhonjiswe kuMfanekiso 3, i-PUD #65215A izolapha ugqinsi lwefilimu olumanzi olungafika ku-7 mils ngemizuzu emi-4 ngezinga lokushisa likahhavini elingu-140 °C. Lokhu kungaphakathi kwefasitela lezingubo eziningi ezelaphekayo ezisuselwa ku-UV. I-PUD #65215A ingakwazi ukunika amandla abafakeli bamanje bezinto ezilaphekayo ze-UV ezincibilikisiwe ukuze bashintshele olwazini olusekelwe emanzini olulapheka nge-UV olunoshintsho oluncane emugqeni wabo wokumboza.

Kubakhiqizi abacabangela ukunwetshwa kokukhiqiza, ukunamathela okusekelwe ku-PUD #65215A kuzobavumela ukuthi:

●Yonga imali ngokusebenzisa ulayini wokuhlanganisa osuselwe emanzini omfushane;

●Iba nezinyathelo ezincane zomugqa wokuhlanganisa endaweni;

●Ukuba nomthelela oncishisiwe kwimvume ye-VOC yamanje;

●Bona ukonga amandla ngenxa yezidingo ezincishisiwe zokomisa.

Sengiphetha, i-PUD #65215A izosiza ukuthuthukisa ukusebenza kahle kokukhiqizwa kwemigqa yokunamathela e-UV ngokusebenzisa ukusebenza okuphezulu okubonakalayo kanye nezici zokukhulula amanzi ngokushesha ze-resin uma yomile ku-140 °C.

Isikhathi sokuthumela: Aug-14-2024