Isizukulwane esisha sama-silicone aphulukisa i-UV nama-epoxies aya ngokuya asetshenziswa ezinhlelweni zezimoto nezogesi.

Zonke izenzo empilweni zibandakanya ukuhwebelana: Ukuthola inzuzo eyodwa ngezindleko kwenye, ukuze kuhlangatshezwane kangcono nezidingo zesimo esikhona. Uma isimo sihilela ukubopha kwevolumu ephezulu, ukuvala uphawu noma ukufaka igesi, abakhiqizi bathembela ezintweni ezinamathelayo ezelapha i-UV ngoba zivumela lapho zidingeka kakhulu futhi zelashwe ngokushesha (imizuzwana engu-1 ukuya kwemi-5 ngemva kokuchayeka kokukhanya).

Ukuhweba, nokho, ukuthi lezi zinto zokunamathisela (i-acrylic, i-silicone ne-epoxy) zidinga i-substrate esobala ukuze iboshwe kahle, futhi zibiza kakhulu kunezinamathiselo ezilapha ngezinye izindlela. Noma kunjalo, abakhiqizi abaningi ezimbonini eziningi baye benza lokhu kuhwebelana amashumi eminyaka ambalwa. Izinkampani eziningi ezengeziwe zizokwenza lokho ngekusasa elibonakalayo. Umehluko, nokho, ukuthi onjiniyela bazosebenzisa i-silicone noma i-epoxy UV-therapy adhesive, njengaleyo esekelwe ku-acrylic.

“Nakuba senze ama-silicone e-UV elaphayo kule minyaka eyishumi edlule noma ngaphezulu, eminyakeni emithathu edlule kudingeke ukuthi siqinise imizamo yethu yokuthengisa ukuze sihambisane nesidingo semakethe,” kuphawula uDoug McKinzie, iphini likamongameli wemikhiqizo ekhethekile kwaNovagard Solutions. "Ukuthengiswa kwethu kwe-silicone ye-UV-cure kwenyuke ngamaphesenti angu-50 eminyakeni embalwa edlule. Lokhu kuzokwehlisa abanye, kodwa sisalindele ukukhula okuhle eminyakeni embalwa ezayo."

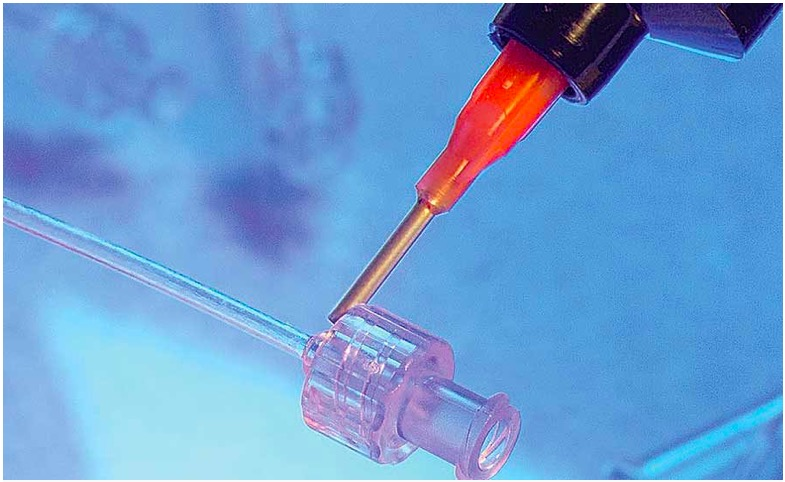

Phakathi kwabasebenzisi abakhulu bama-silicone e-UV-cure kukhona ama-OEM ezimoto, nabahlinzeki be-Tier 1 kanye ne-Tier 2. Umhlinzeki oyedwa weTier 2 usebenzisa i-Loctite SI 5031 sealant esuka ku-Henkel Corp. ukuze afake amatheminali ezindlini zamamojula okulawula amabhuleki kagesi nezinzwa zokucindezela isondo. Le nkampani futhi isebenzisa i-Loctite SI 5039 ukwenza igasket ye-silicone elashwe endaweni ye-UV ezungeze umjikelezo wemojuli ngayinye. UBill Brown, umphathi wezinhlelo zokusebenza zobunjiniyela be-Henkel, uthi yomibili le mikhiqizo iqukethe udayi we-fluorescent ukusiza ukuqinisekisa ubukhona bokunamathela ngesikhathi sokuhlolwa kokugcina.

Le subassembly ibe isithunyelwa kumhlinzeki weSigaba 1 ofaka izingxenye zangaphakathi ezengeziwe futhi axhume i-PCB kumatheminali. Isembozo sibekwe phezu kwe-gasket ye-perimeter ukuze kwakhiwe uphawu oluqinile ekuhlanganiseni kokugcina.

Izinamatheliso ze-epoxy ze-UV nazo zivame ukusetshenziselwa izinhlelo zokusebenza zezimoto nezabathengi. Esinye sezizathu ukuthi lezi zinamathiselo, njengama-silicones, akhiwe ngokuqondile ukuze afane nobude begagasi bemithombo yokukhanya ye-LED (320 kuya ku-550 nanometers), ngakho abakhiqizi bathola zonke izinzuzo zokukhanyisa kwe-LED, njengempilo ende, ukushisa okulinganiselwe kanye nezilungiselelo ezivumelana nezimo. Esinye isizathu izindleko zemali ephansi zokwelashwa kwe-UV, okwenza kube lula ngezinkampani ukuhweba kuze kufike kulobu buchwepheshe.

Isikhathi sokuthumela: Aug-04-2024